お電話ください

+86-19858305627

私達に電子メールを送り

sales@maple-machinery.com

船舶用ステンレス鋳物メーカー

当工場では、砂型鋳造、クローズドダイ鍛造、オープンダイ鍛造などを行っております。卓越したデザイン、高品質の原材料、高性能、そして競争力のある価格は、すべてのお客様が望んでいるものであり、それは私たちがあなたに提供できるものでもあります。私たちは高品質、リーズナブルな価格、完璧なサービスを提供します。

人気の製品

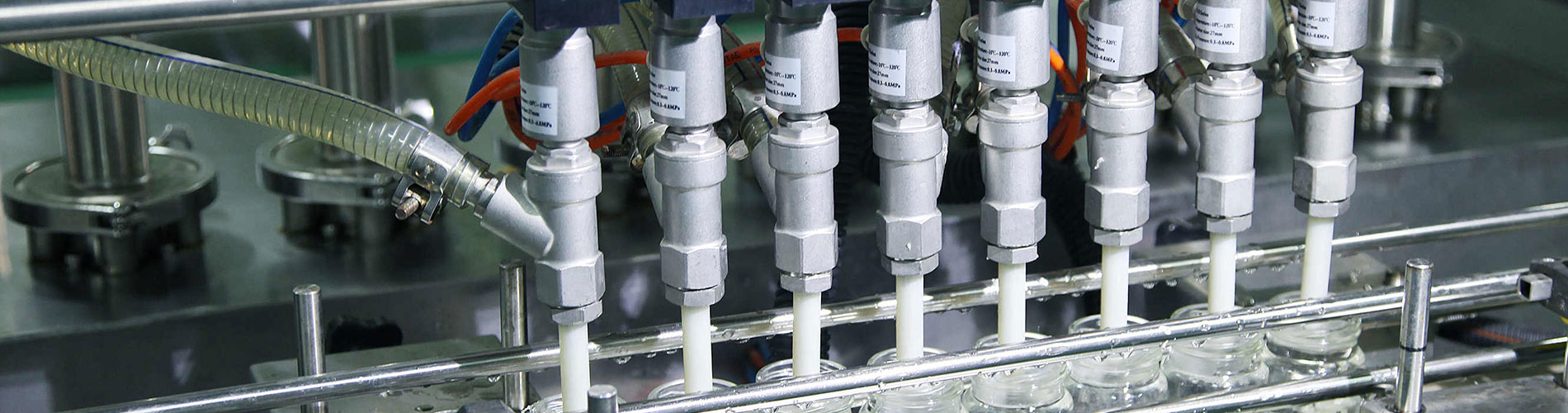

バルブステンレス鋳物部品

メープル機械は、バルブのステンレス鋼鋳造部品の製造に取り組んできました。鉄道、風力産業、オフショア、建設、産業機械のリーダーである Maple の機械チームは、経験豊富でダイナミックです。お客様に対する姿勢と開発を続ける粘り強さが、優れたサービスと品質を保証します建設機械鉄砂型鋳造部品

Maple Machineryは、中国の寧波に本社を置く、高品質の鋳鉄および鋼鋳物の革新的なメーカーです。高精度で複雑な建設機械用鉄砂型鋳造部品の世界的に認められた大手サプライヤーです。私たちのチームは、最高の顧客満足度を確保するために、各プロジェクトの品質に取り組んでいます。建設機械 鉄鋼 精密鋳造部品

Maple 機械は、最高品質の建設機械スチール精密鋳造部品、熟練した製造、組み込み精度を製造しています。私たちの基準によれば、最高のものだけが十分であるため、私たちは純粋な品質を提供します.当社のチームは、お客様のプロセス要件に関係なく、常に最適なソリューションを目指しています。石油・ガス産業用ステンレス鋼鍛造部品

Maple Machinery は中国の寧波に拠点を置き、石油・ガス産業用ステンレス鋼鍛造部品の製造、倉庫保管および二次輸送を行っており、石油・ガス業界の主要サプライヤーのニーズを満たす有利な立場にあります。複数の国の顧客からの認定および承認されたサプライヤーと組み合わせることで、低コストの国からの調達の利点を活用する機会が得られ、Maple の製品のおかげで 100% の品質保証があることを知ることができます。バルブ鋼精密鋳造部品

Maple の機械は、優れた品質を提供しながらお客様と一貫性を保つことで、当社の成功に貢献してきました。バルブ鋼精密鋳造部品は、当社が製造する鋼精密鋳造部品の一種です。各スチール精密鋳造部品をうまく行うには?誠実さは、私たちの最善のポリシーでもあります。私たちの哲学はシンプルです。私たちは約束を果たします。しかし、業界の他の企業と私たちを際立たせているのは、戦略的投資です。私たちは設備に投資し、製品を最高かつ最も完璧なものにするよう努めています.マリンステンレス鋳造部品

Maple machinery is a professional manufacturer located in Ningbo, China. More than 15 years of experience in the steel industry. Our products mainly include Marine Stainless Steel Casting Parts. Our products have been exported to many countries in Europe and America. We have a wealth of foundry experience, but also a number of stable Marine industry customers.产品内容 Product Introduction Maple machinery offers a wide range of custom Marine Stainless Steel Casting Parts. Stainless steel is resistant to corrosion and heat, has aesthetic appeal and low life cycle cost, is fully recyclable and has a good strength-to-weight ratio. We offer austenite, ferrite, martensite and biphase grades: we have hot or cold rolled and various surface treatments such as bright annealing. You can count on our experience. 2. Product Parameter (Specification) Item Marine Stainless Steel Casting Parts Roughness Ra 1.6 Tolerance ±0.01mm Material Casting Steel Certification ISO 9001:2015 Weight 0.01-2000KG Machining CNC Heat Treatment Quenching & Tempering Inspection MT/UT/X-Ray Lead Time 30 Days Package Plywood Case Method Investment Casting Capacity 50000 Pcs / Month Origin Ningbo, China 3. Maple’s Service for Marine Maple machinery has been the most demanding supplier of Marine Stainless Steel Casting Parts for more than 15 years. Our reputation has earned us partners and valued customers who follow the most stringent requirements in terms of microstructure integrity, dimensional tolerances and quality control. Our products meet customers' requirements and standards. 4.Supporting Service for Marine As mentioned above, in order to work in adverse conditions, the performance of the Marine Stainless Steel Casting Parts must be excellent. Therefore, it’s not enough to only produce raw castings or forgings, but also need heat treatment, machining, surface treatment, NDT testing, etc. Heat treatment: heat treatment is the critical step to improve the mechanical properties of the workpiece. We can formulate the process according to the strength requirements of the parts, and improve the mechanical properties of the parts such as hardness, yield strength, tensile strength and elongation by heat treatment Machining: we have our own machine shop, and can complete almost all machining requirements with advanced equipment. Surface treatment: the purpose of surface treatment is to make parts work in adverse environment. Zinc plating can prevent parts from rusting; Nickel plating can enhance the wear resistance and corrosion resistance of parts; Phosphating can prevent parts from corrosion… Non-destructive testing (NDT): NDT is the last and most important step. Maple will NDT the parts to ensure that there are no surface defects (such as cracks, sand holes, blow holes) and no internal defects (shrinkage and slag) on the delivered parts. Common Material for Mining Industry We have the ability to manufacture all steel standard materials as well as special materials. The following are our common materials for manufacturing Marine Stainless Steel Casting Parts: Carbon Steel:1015, 1020, 1035, 1045, 20Mn, 25Mn, A570.GrA, SJ355, C45… Alloy Steel:4130, 4135, 4140, 4340, 8620, 8640, 20CrMo, 42CrMo4, 34CrNiMo6, 25CrMo… Stainless steel:304, 304L, 316, 316L, 410, 416, CF8, CF8M, PH17-4, CK20… Gray Iron:GG-15, GG-20, GG-25, Class 20B, Class 25B, Class 30B, GJL-250, GJL-300… Ductile Iron:GGG-40, GGG-50, 60-40-18, 65-45-12, 70-50-05, 80-55-06 QT500-7, QT400-18, QT700-2 … High Chromium cast iron:15%Cr-Mo-HC, 20%Cr-Mo-LC, 25%Cr… Aluminum:AlSi7Mg, AlSi12, AlSi10Mg, A356, A360… High Manganese steel: X120Mn12, Mn12, Mn13… 5.The Parts We Supplying for The Marine We have manufactured a wide range of Marine Stainless Steel Casting Parts. The following are typical products: Ground engaging tools: drill bits, carbide tipped tool, forged bucket tooth, auger.... 6.Why Investment Casting Investment casting is a leading process used for the production of high-quality castings and is used to make metal alloys. The key advantage of the investment casting process is that it can help to cast metals with high melting temperatures and create parts with complex geometry that are much needed in industries like aircraft, automotive, and military. As professional investment casting manufacturer, our specialized technique is widely applied to get heavier, stronger, and complex shapes for investment castings. When you trade with us, you get several benefits such as lower costs, a cheaper molding process for complex designs, and higher accuracy. Another competitive benefit enjoyed by Maple Machinery is its leading position in China for casting technology. We will provide precision castings and micron-level processing services.

お問い合わせを送信

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy