お電話ください

+86-19858305627

私達に電子メールを送り

sales@maple-machinery.com

食品加工機械鋼インベストメント鋳造部品メーカー

当工場では、砂型鋳造、クローズドダイ鍛造、オープンダイ鍛造などを行っております。卓越したデザイン、高品質の原材料、高性能、そして競争力のある価格は、すべてのお客様が望んでいるものであり、それは私たちがあなたに提供できるものでもあります。私たちは高品質、リーズナブルな価格、完璧なサービスを提供します。

人気の製品

バルブダクタイル鋳鉄鋳造部品

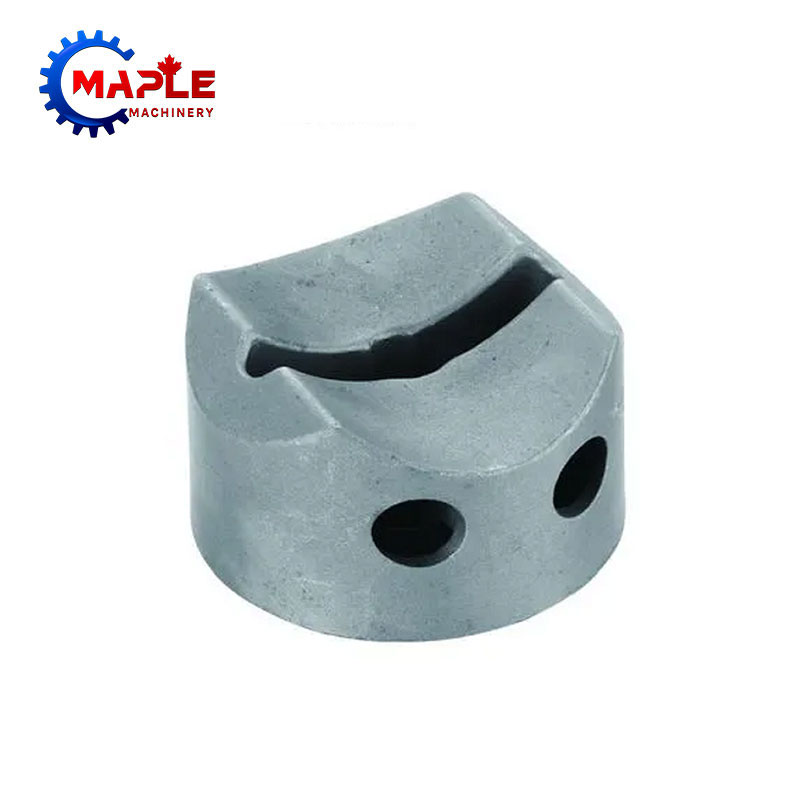

Maple Machinery は、豊富な技術知識と高度な資格を持つチームを備え、お客様のニーズに合わせてカスタマイズされたバルブダクタイル鋳鉄鋳造部品ソリューションを開発しています。 Valve の中長期的な目標を念頭に置き、すべての利害関係者との関係における機密保持、説明責任、持続可能性を優先します。顧客との相互合意によって定義された技術要件により、カスタマイズされたサービスが提供されます。サービス チームは、プロジェクト開発からアフターセールスまで、迅速な対応と直接的な透明性を追求します。お客様の要件と仕様に応じた鋳造ソリューションを提供します。重工業用鋼密閉型鍛造部品

メイプルマシナリーは密閉型鍛造を専門とし、高品質の重工業用鋼密閉型鍛造部品を製造しています。私たちの事業範囲はグローバルマーケティングです。現在、同社は国内外の多くの有名な顧客と長期的な協力関係を確立しています。 Maple 機械の文化は、自己搾取のための価値を生み出すことです。その最大の受益者は顧客です。その結果、メープル機械はこれまでも、そしてこれからもお客様にとって信頼できる献身的なパートナーであり続けるでしょう。食品機械 鉄鋼 精密鋳造部品

私たちは、食品加工機械鋼の精密鋳造部品の分野における大手メーカーおよびサプライヤーです。当社の製品範囲は、さまざまな業界基準に照らして品質チェックされています。私たちは、食品加工業界向けの部品のカスタマイズに 15 年以上の経験があります。ドライブシャフト、ドライブトレイン、トランスミッション、コンポーネントを幅広く取り揃えています。有能な専門家を多数採用しています。当社の専門家は、お客様の要件を理解しようとします。農機具 ステンレス鋳物部品

We have rich experience in the field of steel, steel, aluminum, special alloy and other agricultural machinery. All Agricultural Machinery Stainless Steel Casting Parts are made by different processes, including sand casting, investment casting, centrifugal casting, die casting, forging, machining, etc. We have been serving international industrial markets for more than 15 years. Our primary goal is to retain the loyalty of existing customers and win new business through exemplary customer service, low cost, high quality, fast shipping, complete order fulfillment and custom processing. 产品内容 Agricultural Machinery Stainless Steel Casting Parts Product Introduction Maple machinery's services include heat treatment, machining and surface treatment. Heat treatment involves heating and cooling a metal to change the physical and mechanical properties of Agricultural Machinery Stainless Steel Casting Parts. Heat treatment controls properties such as hardness, strength, toughness, ductility, and elasticity. We also offer a full range of machining services. With our surface treatment service, we can treat your products to improve corrosion resistance, wear resistance and appearance. 2. Product Parameter (Specification) Item Agricultural Machinery Stainless Steel Casting Parts Roughness Ra 1.6 Tolerance ±0.01mm Material Casting Steel Certification ISO 9001:2015 Weight 0.01-2000KG Machining CNC Heat Treatment Quenching & Tempering Inspection MT/UT/X-Ray Lead Time 30 Days Package Plywood Case Method Investment Casting Capacity 50000 Pcs / Month Origin Ningbo, China 3. Maple’s Service for Agricultural Machinery Maple machinery is one of the trusted and reliable manufacturers and suppliers of Stainless Steel Casting Parts, Vick serves the global needs of Agricultural Machinery Stainless Steel Casting Parts and ensures high quality products and on-time delivery in every transaction. In our foundry, we mainly process carbon steel and alloy steel materials. We inherited the casting process from our great-grandfather, and have a skilled labor force and professional technical experts to meet different needs. 4.Supporting Service for Agricultural Machinery As mentioned above, in order to work in adverse conditions, the performance of the Agricultural Machinery Stainless Steel Casting Parts must be excellent. Therefore, it’s not enough to only produce raw castings or forgings, but also need heat treatment, machining, surface treatment, NDT testing, etc. Heat treatment: heat treatment is the critical step to improve the mechanical properties of the workpiece. We can formulate the process according to the strength requirements of the parts, and improve the mechanical properties of the parts such as hardness, yield strength, tensile strength and elongation by heat treatment Machining: we have our own machine shop, and can complete almost all machining requirements with advanced equipment. Surface treatment: the purpose of surface treatment is to make parts work in adverse environment. Zinc plating can prevent parts from rusting; Nickel plating can enhance the wear resistance and corrosion resistance of parts; Phosphating can prevent parts from corrosion… Non-destructive testing (NDT): NDT is the last and most important step. Maple will NDT the parts to ensure that there are no surface defects (such as cracks, sand holes, blow holes) and no internal defects (shrinkage and slag) on the delivered parts. Common Material for Mining Industry We have the ability to manufacture all steel standard materials as well as special materials. The following are our common materials for manufacturing Agricultural Machinery Stainless Steel Casting Parts: Carbon Steel:1015, 1020, 1035, 1045, 20Mn, 25Mn, A570.GrA, SJ355, C45… Alloy Steel:4130, 4135, 4140, 4340, 8620, 8640, 20CrMo, 42CrMo4, 34CrNiMo6, 25CrMo… Stainless steel:304, 304L, 316, 316L, 410, 416, CF8, CF8M, PH17-4, CK20… Gray Iron:GG-15, GG-20, GG-25, Class 20B, Class 25B, Class 30B, GJL-250, GJL-300… Ductile Iron:GGG-40, GGG-50, 60-40-18, 65-45-12, 70-50-05, 80-55-06 QT500-7, QT400-18, QT700-2 … High Chromium cast iron:15%Cr-Mo-HC, 20%Cr-Mo-LC, 25%Cr… Aluminum:AlSi7Mg, AlSi12, AlSi10Mg, A356, A360… High Manganese steel: X120Mn12, Mn12, Mn13… 5.The Parts We Supplying for The Agricultural Machinery We have manufactured a wide range of Agricultural Machinery Stainless Steel Casting Parts. The following are typical products: Brackets, Rototiller tines, Tillage Points, Seed Drills, Chain Sprocket Locust Harrows, Levers, Plough, Pivots, Covers, Clevises, Handles and Latches, Suitcase Weights, Pumps & Valves, and Hardware.. 6.Why Investment Casting Investment casting is a leading process used for the production of high-quality castings and is used to make metal alloys. The key advantage of the investment casting process is that it can help to cast metals with high melting temperatures and create parts with complex geometry that are much needed in industries like aircraft, automotive, and military. As professional investment casting manufacturer, our specialized technique is widely applied to get heavier, stronger, and complex shapes for investment castings. When you trade with us, you get several benefits such as lower costs, a cheaper molding process for complex designs, and higher accuracy. Another competitive benefit enjoyed by Maple Machinery is its leading position in China for casting technology. We will provide precision castings and micron-level processing services.建設機械鋼インベストメント鋳造部品

Maple Machineryは、鋳造と機械加工を専門とする近代的な工場であり、建設機械鋼インベストメント鋳造部品の信頼できる名前です。私たちは卓越した才能を持つチームであり、お客様のニーズを満たすためにテクノロジーに対応することを固く信じています。すべての鋳造および機械工場はISO9001:2015認証に合格しています。私たちに地理的な利点を与えるのは、輸出ビジネスを強化する港湾都市としての寧波の戦略的な場所です。船舶用鋼鍛造部品

鋼鍛造は金属鍛造の代表的なもので、局所的な圧縮力を利用して鋼を成形する技術です。鍛造品は大幅な変化を遂げ、プロセスがより効率的で、より速く、より長く持続するようになりました。現在、船舶用鋼鍛造部品は通常、電動、油圧、または圧縮空気駆動の鍛造プレスまたはハンマーツールを使用して完成されます。熱間鍛造では、ワークピースを溶融温度の約 75% まで加熱します。

お問い合わせを送信

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy