お電話ください

+86-19858305627

私達に電子メールを送り

sales@maple-machinery.com

ケータリング機器のインベストメント鋳造部品メーカー

当工場では、砂型鋳造、クローズドダイ鍛造、オープンダイ鍛造などを行っております。卓越したデザイン、高品質の原材料、高性能、そして競争力のある価格は、すべてのお客様が望んでいるものであり、それは私たちがあなたに提供できるものでもあります。私たちは高品質、リーズナブルな価格、完璧なサービスを提供します。

人気の製品

ハイウェイ産業の鋼鉄失われたワックスの鋳造の部品を離れて

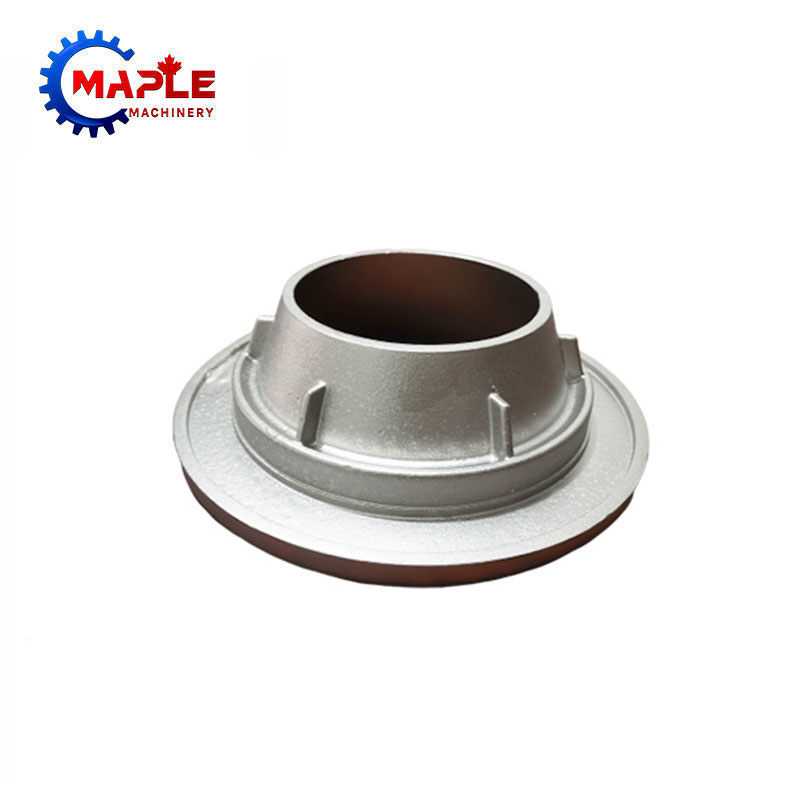

Maple machinery has a number of casting plants, with strong processing capacity Specializing in the production of carbon steel, alloy steel, stainless steel, high temperature alloy and other wax lost casting parts and machining parts. Maple's superior quality of Off Highway Industry Steel Lost Wax Casting Parts attracts equally excellent customers, enabling our products to serve various machinery industries. 产品内容 Off Highway Industry Steel Lost Wax Casting Parts Product Introduction Off Highway Industry Steel Lost Wax Casting Parts is a product that Maple machinery has been doing. Lost wax casting is now called investment casting. It is a precision casting process with little or no cutting. It is not only suitable for precision casting of various types and alloys, but also produces castings with higher dimensional accuracy and surface quality than other precision casting methods. In order to meet the needs of different customers, we use two kinds of wax, namely yellow low temperature wax and green medium temperature wax. 2. Product Parameter (Specification) Item Off Highway Industry Steel Lost Wax Casting Parts Roughness Ra 1.6 Tolerance ±0.01mm Material Casting Steel/Casting Iron Certification ISO 9001:2015 Weight 0.01-5000KG Machining CNC Heat Treatment Quenching & Tempering Inspection MT/UT/X-Ray Lead Time 30 Days Package Plywood Case Method Sand Casting Capacity 50000 Pcs / Month Origin Ningbo, China 3. Maple’s Services for Off Highway Industry Maple machinery has been increasing its manufacturing capacity for Off Highway Industry Steel Lost Wax Casting Parts for many years. Provide high quality Off Highway Industry Steel Lost Wax Casting Parts for our machining operations to meet and satisfy customer needs. We are able to process different types of castings, including: pressure die casting and sand castings. We assist our customers to select the most appropriate casting type according to the required volume and complexity, providing the most cost effective solution. The railway sector provides a crucial network for transport and distribution. It needs cost-effective and long-lasting equipment that is dependable for the range of applications. The railways, from freight to passenger, need different castings for various applications. Maple Machinery carries extensive experience to create steel castings and iron castings in varying sizes, shapes, and materials that are precise, strong, and durable. We manufacture a wide range of castings and forgings for railway infrastructure and transportation equipment. 4.Supporting Service for Off Highway Industry parts As mentioned above, in order to work in adverse conditions, the performance of the Off Highway Industry Steel Lost Wax Casting Parts must be excellent. Therefore, it’s not enough to only produce raw castings or forgings, but also need heat treatment, machining, surface treatment, NDT testing, etc. Heat treatment: heat treatment is the critical step to improve the mechanical properties of the workpiece. We can formulate the process according to the strength requirements of the parts, and improve the mechanical properties of the parts such as hardness, yield strength, tensile strength and elongation by heat treatment Machining: we have our own machine shop, and can complete almost all machining requirements with advanced equipment. Surface treatment: the purpose of surface treatment is to make parts work in adverse environment. Zinc plating can prevent parts from rusting; Nickel plating can enhance the wear resistance and corrosion resistance of parts; Phosphating can prevent parts from corrosion… Non-destructive testing (NDT): NDT is the last and most important step. Maple will NDT the parts to ensure that there are no surface defects (such as cracks, sand holes, blow holes) and no internal defects (shrinkage and slag) on the delivered parts. Common Material for Off Highway Industry parts We have the ability to manufacture all steel standard materials as well as special materials. The following are our common materials for manufacturing Off Highway Industry Steel Lost Wax Casting Parts: Carbon Steel:1015, 1020, 1035, 1045, 20Mn, 25Mn, A570.GrA, SJ355, C45… Alloy Steel:4130, 4135, 4140, 4340, 8620, 8640, 20CrMo, 42CrMo4, 34CrNiMo6, 25CrMo… Stainless steel:304, 304L, 316, 316L, 410, 416, CF8, CF8M, PH17-4, CK20… Gray Iron:GG-15, GG-20, GG-25, Class 20B, Class 25B, Class 30B, GJL-250, GJL-300… Ductile Iron:GGG-40, GGG-50, 60-40-18, 65-45-12, 70-50-05, 80-55-06 QT500-7, QT400-18, QT700-2 … High Chromium cast iron:15%Cr-Mo-HC, 20%Cr-Mo-LC, 25%Cr… Aluminum:AlSi7Mg, AlSi12, AlSi10Mg, A356, A360… High Manganese steel: X120Mn12, Mn12, Mn13… 5.The Parts We Supplying for the Off Highway Industry We have manufactured a wide range of Off Highway Industry Steel Lost Wax Casting Parts. The following are typical products: Coupling components, Centre plates, Bearing brackets, Rail wheels, Wheel hub, Base plate, Axle boxes, Yokes, Pedestals, Hinges, Tie plates, Side jaw clip, and Joint bar. 6. Why Sand Casting Sand casting is an ancient casting process where the metal parts are molded by pouring metal into a hollow cavity. The mold-based manufacturing process is used to make castings with materials of iron, steel, and Aluminum. Casting-based manufacturing includes several steps and can create a wide range of shapes and sizes for metal products. The process begins with the making of a mold pattern and a gate system with the exact size and shape of the required part. The temperature required depends on the metal as some metals take a long time to heat and melt. Maple Machinery has continuously upgraded its Sand-casting equipment and refined the casting process. The aim behind this is to use only the advanced casting technology for its Sand-casting operations. Each step follows the customer’s drawings and instructions to deliver precise solutions.石油およびガス産業の鋼砂鋳造部品

Maple Machinery は、世界中の石油・ガス産業向けに高品質の石油・ガス産業用鋼砂鋳造部品を製造しています。当社の目標は、石油・ガス業界の砂型鋳造部品の市場代替品とより信頼性の高いソリューションを提供し、高品質の部品を作成することで、寿命が長くなり予定通りに供給されるだけでなく、より低コストで供給できるようにすることです。したがって、最高品質の部品など、顧客の時間の節約が最小限に抑えられます。建設機械鉄砂型鋳造部品

Maple Machineryは、中国の寧波に本社を置く、高品質の鋳鉄および鋼鋳物の革新的なメーカーです。高精度で複雑な建設機械用鉄砂型鋳造部品の世界的に認められた大手サプライヤーです。私たちのチームは、最高の顧客満足度を確保するために、各プロジェクトの品質に取り組んでいます。バルブダクタイル鋳鉄鋳造部品

Maple Machinery は、豊富な技術知識と高度な資格を持つチームを備え、お客様のニーズに合わせてカスタマイズされたバルブダクタイル鋳鉄鋳造部品ソリューションを開発しています。 Valve の中長期的な目標を念頭に置き、すべての利害関係者との関係における機密保持、説明責任、持続可能性を優先します。顧客との相互合意によって定義された技術要件により、カスタマイズされたサービスが提供されます。サービス チームは、プロジェクト開発からアフターセールスまで、迅速な対応と直接的な透明性を追求します。お客様の要件と仕様に応じた鋳造ソリューションを提供します。リサイクル産業ねずみ鋳鉄部品

メープル機械砂型鋳造プロセスは、リサイクル産業ねずみ鋳鉄部品を生産します。砂型は木や金属の型で作られます。細粒砂を高速ミキサーで樹脂バインダーと混合し、模様のある箱に注ぎました。数分後、砂と接着剤の混合物が硬化し、型から型が剥がされました。鋳物の内部構造を作るために使用される中子にも同じプロセスが使用されます。土木用鋼密閉型鍛造部品

中国の寧波にある Maple Machinery Co., Ltd. は、20 年以上にわたり、顧客に高品質の土木用鋼密閉型鍛造部品を提供することに特化した密閉型鍛造品の専門メーカーです。さらに、完成品に対してその他の付加価値サービスも提供できます。鍛造部品・機械加工部品が必要な場合は、お気軽にお問い合わせください。

お問い合わせを送信

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy