お電話ください

+86-19858305627

私達に電子メールを送り

sales@maple-machinery.com

林業機械鋼インベストメント鋳造メーカー

当工場では、砂型鋳造、クローズドダイ鍛造、オープンダイ鍛造などを行っております。卓越したデザイン、高品質の原材料、高性能、そして競争力のある価格は、すべてのお客様が望んでいるものであり、それは私たちがあなたに提供できるものでもあります。私たちは高品質、リーズナブルな価格、完璧なサービスを提供します。

人気の製品

鉱業鉄鋼インベストメント鋳造部品

Maple Machineryは、鉱業の鉄鋼インベストメント鋳造部品の製造において豊富な経験を持っています。寧波に鋳造所と機械工場を持つワンストップメーカーとして。私たちは長年、鋼のインベストメント鋳造と仕上げ加工を専門としています。私たちの鋳物は競争力のある価格優位性を持っており、ヨーロッパとアメリカの市場のほとんどをカバーしています。私たちはあなたの中国での長期的なパートナーになることを楽しみにしています。重工業用砂鉄鋳造部品

中国の寧波にある Maple Machinery は、重工業用途向けの広範な重工業用砂鉄鋳造部品を生産する鋳物工場です。また、ディーゼル エンジンのピストン リング、シリンダー ライナー、コネクティング ロッドなどの高性能エンジン部品も製造しています。当社は、世界最高品質の砂鉄鋳造のサプライヤーとしての評判を得ていることを誇りに思っています。それは、当社の品質と顧客への取り組みがお客様のために実現されるからです。船舶用鋼鍛造部品

鋼鍛造は金属鍛造の代表的なもので、局所的な圧縮力を利用して鋼を成形する技術です。鍛造品は大幅な変化を遂げ、プロセスがより効率的で、より速く、より長く持続するようになりました。現在、船舶用鋼鍛造部品は通常、電動、油圧、または圧縮空気駆動の鍛造プレスまたはハンマーツールを使用して完成されます。熱間鍛造では、ワークピースを溶融温度の約 75% まで加熱します。重工業用鋼砂鋳造部品

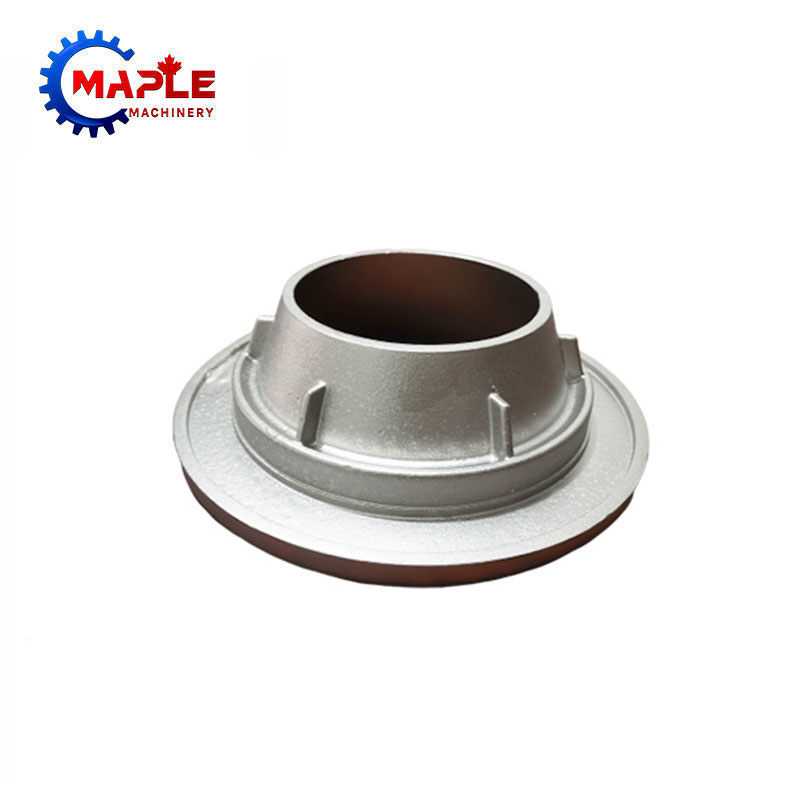

Maple Machinery は高品質の重工業用鋼砂鋳造部品を専門とし、高品質の大量生産注文と単品生産を提供します。鋳造工場の主な材料はさまざまなグレードの鋼です。高品質の鋳造準備型により、最小限のマージンで後続の加工が可能になります。鋳鋼は複雑な形状の製品を提供するため、多くの場合、複雑な構造の金属製品を製造する唯一の方法です。リサイクル産業用鋼鍛造部品

Maple Machinery は、お客様に高品質のリサイクル産業用鋼鍛造部品を提供し、完璧な品質の部品の所有権を確保し、最大の再現性と最適な生産性/競争力を確保し、輸送機器の予防保守を保証します。定期的な安全検査と、該当する場合は改修と改善を行います。機械設置のためのより効率的で信頼性の高い基盤を提供するために実行されます。建設機械鋼クローズドダイ鍛造部品

Mapleの建設機械鋼製クローズドダイ鍛造部品は、米国およびヨーロッパの建設機械メーカーによって使用されています。これは、掘削機の油圧シリンダー部分、掘削マニピュレーターのジョイント部分、および大型建設機械のステアリングシステムの制御部分です。それは建設機械の最も重要な部分です。建設機械鋼クローズドダイ鍛造当社の部品は高強度合金鋼でできており、製造工程は高度な金属鍛造工程です。鍛造品の内部材料はよく整理されており、欠陥がないため、建設機械の高強度操作のニーズを満たすことができます。高品質の建設機械を製造するための好ましいコンポーネントです。

お問い合わせを送信

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy