製品

- View as

リサイクル産業 スチール ロストワックス 鋳造部品

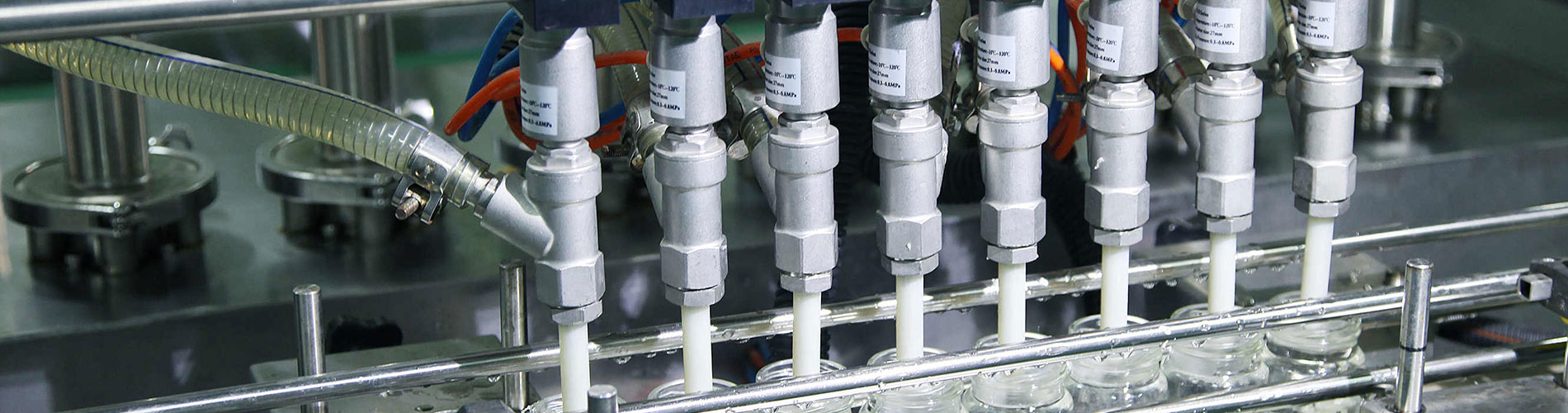

Maple 機械には、製品とサービスの包括的なポートフォリオがあります。その結果、個別に設計された Recycling Industry Steel Lost Wax Casting Parts カスタム ツールと高性能標準製品を使用して、プロセスの信頼性、精度、および費用対効果の要件を最もよく満たす処理ソリューションを作成します。

続きを読むお問い合わせを送信リサイクル産業 鉄鋼精密鋳造部品

Maple 機械は、常に最高品質のオーダーメイドのリサイクル産業用鋼精密鋳造部品サービスを提供してきました。私たちはお客様に最高レベルの品質の部品とサービスを提供します。当社のリサイクル産業スチール精密鋳造部品サービスは、お客様の正確なニーズを満たすように設計されており、当社のチームは、精密エンジニアリングと革新的なツール機能を通じて価値を提供することに取り組んでいます。

続きを読むお問い合わせを送信リサイクル産業 鋳鋼部品

メープル機械は、鋳鋼のサプライヤです。 「ロストワックス」法は、複雑な鋳物を非常に高い精度で製造するために使用されます。この一般的なアプローチの結果として、当社のエンジニアは、製品設計、リサイクル産業の鋼鋳造部品、および材料の選択においてかなりの自由度を持っています。これは、お客様と相談して、お客様の正確な要望と要件を満たすリサイクル業界向けの最高の鋳物を製造できることを意味します。メープルマシナリーは、鋳造を成功させるための開発パートナーであり、相互の協議を通じて最高の鋳造を実現することを目標としています。

続きを読むお問い合わせを送信ハイウェイ産業のステンレス鋼の鋳造部品を離れて

要求された製品に最適な鋳造パラメーターを提供するために、Maple 機械は最新の CAD 技術を使用してオフハイウェイ産業のステンレス鋼鋳造部品を製造し、お客様に競争力のあるコストでワックス射出成形金型を提供します。ワックス射出成形金型の寸法の一貫性を提供およびサポートする治具は、測定精度を再現するために、部品の技術図面の寸法に従って自己設計されています。

続きを読むお問い合わせを送信石油・ガス産業のステンレス鋼鋳造部品

Maple の機械はあらゆる種類の金属を処理し、当社の経験により、石油およびガス産業のステンレス鋼鋳造部品の製造を簡単に完了することができます。ステンレス鋼は、当社の研究室で一般的な材料の 1 つです。パートナーシップを通じて完全なサービスを提供し、適応的で多様な供給源を提供することにより、技術的および経済的ソリューションを提供することができます。生産チェーン全体を内部的に統合して、応答性、技術的習熟度、および品質を確保します。そして、経済的最適化のための提案。

続きを読むお問い合わせを送信農機具 ステンレス鋳物部品

We have rich experience in the field of steel, steel, aluminum, special alloy and other agricultural machinery. All Agricultural Machinery Stainless Steel Casting Parts are made by different processes, including sand casting, investment casting, centrifugal casting, die casting, forging, machining, etc. We have been serving international industrial markets for more than 15 years. Our primary goal is to retain the loyalty of existing customers and win new business through exemplary customer service, low cost, high quality, fast shipping, complete order fulfillment and custom processing. 产品内容 Agricultural Machinery Stainless Steel Casting Parts Product Introduction Maple machinery's services include heat treatment, machining and surface treatment. Heat treatment involves heating and cooling a metal to change the physical and mechanical properties of Agricultural Machinery Stainless Steel Casting Parts. Heat treatment controls properties such as hardness, strength, toughness, ductility, and elasticity. We also offer a full range of machining services. With our surface treatment service, we can treat your products to improve corrosion resistance, wear resistance and appearance. 2. Product Parameter (Specification) Item Agricultural Machinery Stainless Steel Casting Parts Roughness Ra 1.6 Tolerance ±0.01mm Material Casting Steel Certification ISO 9001:2015 Weight 0.01-2000KG Machining CNC Heat Treatment Quenching & Tempering Inspection MT/UT/X-Ray Lead Time 30 Days Package Plywood Case Method Investment Casting Capacity 50000 Pcs / Month Origin Ningbo, China 3. Maple’s Service for Agricultural Machinery Maple machinery is one of the trusted and reliable manufacturers and suppliers of Stainless Steel Casting Parts, Vick serves the global needs of Agricultural Machinery Stainless Steel Casting Parts and ensures high quality products and on-time delivery in every transaction. In our foundry, we mainly process carbon steel and alloy steel materials. We inherited the casting process from our great-grandfather, and have a skilled labor force and professional technical experts to meet different needs. 4.Supporting Service for Agricultural Machinery As mentioned above, in order to work in adverse conditions, the performance of the Agricultural Machinery Stainless Steel Casting Parts must be excellent. Therefore, it’s not enough to only produce raw castings or forgings, but also need heat treatment, machining, surface treatment, NDT testing, etc. Heat treatment: heat treatment is the critical step to improve the mechanical properties of the workpiece. We can formulate the process according to the strength requirements of the parts, and improve the mechanical properties of the parts such as hardness, yield strength, tensile strength and elongation by heat treatment Machining: we have our own machine shop, and can complete almost all machining requirements with advanced equipment. Surface treatment: the purpose of surface treatment is to make parts work in adverse environment. Zinc plating can prevent parts from rusting; Nickel plating can enhance the wear resistance and corrosion resistance of parts; Phosphating can prevent parts from corrosion… Non-destructive testing (NDT): NDT is the last and most important step. Maple will NDT the parts to ensure that there are no surface defects (such as cracks, sand holes, blow holes) and no internal defects (shrinkage and slag) on the delivered parts. Common Material for Mining Industry We have the ability to manufacture all steel standard materials as well as special materials. The following are our common materials for manufacturing Agricultural Machinery Stainless Steel Casting Parts: Carbon Steel:1015, 1020, 1035, 1045, 20Mn, 25Mn, A570.GrA, SJ355, C45… Alloy Steel:4130, 4135, 4140, 4340, 8620, 8640, 20CrMo, 42CrMo4, 34CrNiMo6, 25CrMo… Stainless steel:304, 304L, 316, 316L, 410, 416, CF8, CF8M, PH17-4, CK20… Gray Iron:GG-15, GG-20, GG-25, Class 20B, Class 25B, Class 30B, GJL-250, GJL-300… Ductile Iron:GGG-40, GGG-50, 60-40-18, 65-45-12, 70-50-05, 80-55-06 QT500-7, QT400-18, QT700-2 … High Chromium cast iron:15%Cr-Mo-HC, 20%Cr-Mo-LC, 25%Cr… Aluminum:AlSi7Mg, AlSi12, AlSi10Mg, A356, A360… High Manganese steel: X120Mn12, Mn12, Mn13… 5.The Parts We Supplying for The Agricultural Machinery We have manufactured a wide range of Agricultural Machinery Stainless Steel Casting Parts. The following are typical products: Brackets, Rototiller tines, Tillage Points, Seed Drills, Chain Sprocket Locust Harrows, Levers, Plough, Pivots, Covers, Clevises, Handles and Latches, Suitcase Weights, Pumps & Valves, and Hardware.. 6.Why Investment Casting Investment casting is a leading process used for the production of high-quality castings and is used to make metal alloys. The key advantage of the investment casting process is that it can help to cast metals with high melting temperatures and create parts with complex geometry that are much needed in industries like aircraft, automotive, and military. As professional investment casting manufacturer, our specialized technique is widely applied to get heavier, stronger, and complex shapes for investment castings. When you trade with us, you get several benefits such as lower costs, a cheaper molding process for complex designs, and higher accuracy. Another competitive benefit enjoyed by Maple Machinery is its leading position in China for casting technology. We will provide precision castings and micron-level processing services.

続きを読むお問い合わせを送信