製品

- View as

バルブ鋼密閉型鍛造部品

当社は、高品質のバルブ鋼密閉型鍛造部品と、バルブ業界およびそれ以外の業界の高い需要を満たす柔軟性と責任を提供します。バルブ部品であろうと、その他の型鍛造部品であろうと、当社はメープル機械で製造しています。同じ品質と顧客重視のアプローチをお楽しみください。鋼の密閉型鍛造品を本格的に開発・生産してみませんか

続きを読むお問い合わせを送信重工業用鋼密閉型鍛造部品

メイプルマシナリーは密閉型鍛造を専門とし、高品質の重工業用鋼密閉型鍛造部品を製造しています。私たちの事業範囲はグローバルマーケティングです。現在、同社は国内外の多くの有名な顧客と長期的な協力関係を確立しています。 Maple 機械の文化は、自己搾取のための価値を生み出すことです。その最大の受益者は顧客です。その結果、メープル機械はこれまでも、そしてこれからもお客様にとって信頼できる献身的なパートナーであり続けるでしょう。

続きを読むお問い合わせを送信食品加工機械鋼鍛造部品

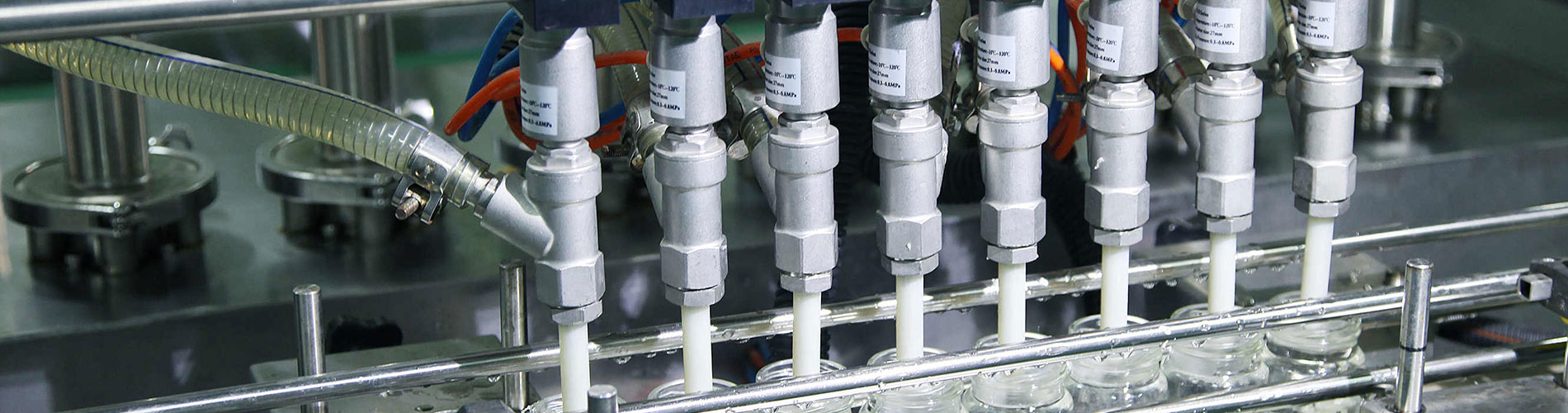

Maple Machinery は、開発目標を達成するために、人材、プロセス、機械の開発に継続的に投資しています。投資と革新により、食品加工機械の鋼鍛造部品の標準が確保されました。継続的な社内開発と完璧さの追求により、当社はお客様から認められてきました。

続きを読むお問い合わせを送信バルブ鋼鍛造部品

We at Maple machinery guarantee the quality and impeccable service of every Valve Steel Forging parts. We strive for excellence every day, using all of our expertise and tremendous commitment to ensure maximum efficiency. We aim at innovation to create a better future and bravely face every new challenge. Product Introduction The different Forging techniques offered by Maple machiney Forging solutions enable us to forge the different Valve Steel Forging parts of valves all of which are designed to the customer's requirements and are also checked and verified in a simulator before forging. The resources and skills of our staff enable us to forge any type of material that is processed on our heat treatment equipment and completed after conducting final destructive and non-destructive tests. They are provided on delivery terms agreed with the customer and include all required documents and certificates. 2. Product Parameter (Specification) Item Valve Steel Forging parts Roughness Ra 1.6 Tolerance ±0.01mm Material Alloy Steel Certification ISO 9001:2015 Weight 0.01-60KG Machining CNC Heat Treatment Quenching & Tempering Inspection MT/UT/X-Ray Lead Time 30 Days Package Plywood Case Method Closed Die Forging Capacity 50000 Pcs / Month Origin Ningbo, China 3. Maple’s Services for Valve Our Valve Steel Forging parts have a worldwide reputation for their high quality and reliability. With our state-of-the-art testing laboratories and highly qualified workforce, we combine the highest standards of technology, quality and productivity. Accurate delivery time, fast service, we get the customer's praise. 4.Supporting Service for Valve parts As mentioned above, in order to work in adverse conditions, the performance of the Valve Valve Steel Forging parts must be excellent. Therefore, it’s not enough to only produce raw castings or forgings, but also need heat treatment, machining, surface treatment, NDT testing, etc. Heat treatment: heat treatment is the critical step to improve the mechanical properties of the workpiece. We can formulate the process according to the strength requirements of the parts, and improve the mechanical properties of the parts such as hardness, yield strength, tensile strength and elongation by heat treatment Machining: we have our own machine shop, and can complete almost all machining requirements with advanced equipment. Surface treatment: the purpose of surface treatment is to make parts work in adverse environment. Zinc plating can prevent parts from rusting; Nickel plating can enhance the wear resistance and corrosion resistance of parts; Phosphating can prevent parts from corrosion… Non-destructive testing (NDT): NDT is the last and most important step. Maple will NDT the parts to ensure that there are no surface defects (such as cracks, sand holes, blow holes) and no internal defects (shrinkage and slag) on the delivered parts. Common Material for Agricultural Machinery We have the ability to manufacture all steel standard materials as well as special materials. The following are our common materials for manufacturing Valve Steel Forging parts: Carbon Steel:1015, 1020, 1035, 1045, 20Mn, 25Mn, A570.GrA, SJ355, C45… Alloy Steel:4130, 4135, 4140, 4340, 8620, 8640, 20CrMo, 42CrMo4, 34CrNiMo6, 25CrMo… Stainless steel:304, 304L, 316, 316L, 410, 416, CF8, CF8M, PH17-4, CK20… Gray Iron:GG-15, GG-20, GG-25, Class 20B, Class 25B, Class 30B, GJL-250, GJL-300… Ductile Iron:GGG-40, GGG-50, 60-40-18, 65-45-12, 70-50-05, 80-55-06 QT500-7, QT400-18, QT700-2 … High Chromium cast iron:15%Cr-Mo-HC, 20%Cr-Mo-LC, 25%Cr… Aluminum:AlSi7Mg, AlSi12, AlSi10Mg, A356, A360… High Manganese steel: X120Mn12, Mn12, Mn13… 5.The Parts We Supplying for the Valve We have manufactured a wide range of Valve Steel Forging parts. The following are typical products: Valve joint, Ball valve body, Gate valve body, Choke valve body,Beer valve body,Purification water brass,Hybrid valve, .... 6. Why Closed Die Forging Compared with casting, forging has its special advantages: 1. In the case of the same material, the mechanical properties of forgings are better than those of castings. 2. The forgings strength is higher and the fatigue resistance is stronger. 3. The forgings has better compactness. 4. There are no internal defects and surface defects. 5. Fast production speed, high efficiency, suitable for mass production of products. 6. The product quality is stable.

続きを読むお問い合わせを送信